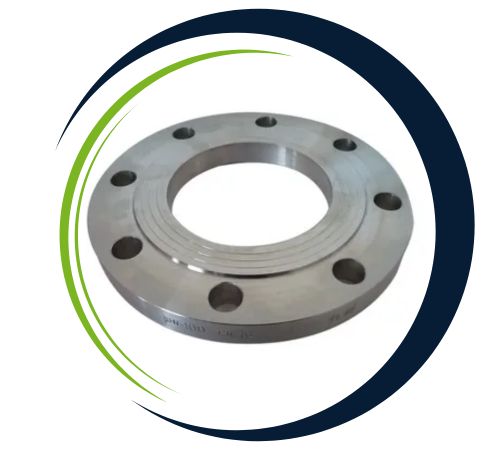

Arda Flanges, based in Istanbul, Turkey, stands out as a top manufacturer and supplier of high-quality Alloy Steel Flanges for clients in Midland, UK. Known for their precision engineering and commitment to international standards, Arda Flanges delivers durable and dependable solutions for industrial piping systems. Their extensive product lineup features various flange types, including weld neck, slip-on, blind, and threaded flanges, all crafted to meet a wide range of operational needs. By blending advanced manufacturing techniques with strict quality control, Arda Flanges guarantees that each product offers optimal performance, corrosion resistance, and longevity, making them a reliable partner for industries throughout the UK.

The Alloy Steel Flanges from Arda Flanges are primarily made up of carbon, chromium, nickel, molybdenum, and a few trace elements, all carefully balanced to boost strength, toughness, and corrosion resistance. These flanges showcase impressive tensile strength, yield strength, and impact resistance, making them perfect for high-pressure and high-temperature applications. Heat treatment processes like quenching and tempering enhance hardness and durability while keeping flexibility intact. The mix of alloying elements ensures they resist oxidation, wear, and chemical degradation, making these flanges trustworthy for demanding industrial settings where structural integrity and long-lasting performance are essential.

| ASTM A182 Flange Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

|---|---|

| ASME SA182m Alloy Steel SORF Flange Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Alloy Steel ASTM A182 Flange Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Alloy Steel Flange Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| Alloy Steel FlangeJIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| Alloy Steel FlangeUNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| ASTM A182 FlangeEN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Most common types of ASME SA182m Alloy Steel Flange | Forged / Threaded / Screwed / Plate |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| ASTM A182 Flange Production technique |

|

| ASTM A182 Alloy Steel Flange Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS 15 NB (1/2″) to 200 NB (8″) Equal and Reducing Configurations |

| ASTM A182 Flange Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| ASTM A182 Alloy Steel Flange Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Alloy Steel ASTM A182 Flange Origin | Indian / West Europe / Japan / USA / Korean |

| Manufacturer of Alloy Steel Flange | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. : -BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange

|

| Alloy Steel Flange Uses & application |

|

| Alloy Steel ASTM A182 Flange Export to | Ireland, Singapore, Indonesia, Ukraine, Saudi Arabia, Spain, Canada, USA, Brazil, Thailand, Korea, Iran, India, Egypt, Oman, Dubai, Peru, etc |

| Grade | C | Mn | Si | S | P | Cr | Mo |

| A182 F5 | ≤0.15 | ≤0.6 | ≤0.5 | ≤0.04 | ≤0.03 | 4-6 | 0.44-0.65 |

| A182 F9 | ≤0.15 | ≤0.6 | 1.00 | ≤0.03 | ≤0.03 | 8-10 | 0.90-1.10 |

| A182 F11 | 0.05-0.2 | 0.3-0.8 | 0.5-1 | ≤0.030 | ≤0.030 | 1-1.5 | 1-1.5 |

| A182 F22 | 0.05-0.15 | 0.3-0.6 | ≤0.5 | ≤0.04 | ≤0.04 | 2-2.5 | 0.87-1.13 |

| A182 F91 | 0.05-0.15 | 0.3-0.6 | ≤0.5 | ≤0.04 | ≤0.04 | 2-2.5 | 0.87-1.13 |

| Grade | Tensile Strength (Mpa) | Yield Strength (Mpa) | Elongation % |

| A182 F5 | 415 – 585 | ≥205 | ≥20 |

| A182 F9 | 380 min | 585 min | ≥30 |

| A182 F11 | 415 – 585 | ≥205 | ≥20 |

| A182 F22 | 415-585 | ≥205 | ≥20 |

| A182 F91 | ≥590 | ≥415 | ≥20 |

Arda Flanges, a leading supplier in Istanbul, Turkey, offers an extensive selection of Alloy Steel Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

Arda Flanges’ Alloy Steel Flanges find extensive use in various industries, including oil and gas, petrochemical, power generation, chemical processing, and water treatment. They play a crucial role in pipelines, connecting pipes, valves, pumps, and other equipment, all while ensuring leak-proof performance even under high pressure and temperature conditions. Their corrosion resistance makes them particularly well-suited for handling harsh environments, ensuring reliability and safety in critical applications. Whether in energy production or chemical processing, these flanges are indispensable components that help maintain the efficiency and integrity of industrial systems.

Yes, we offer custom sizes for Alloy Steel Flanges to meet specific project needs. Our team at Arda Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@ardaflanges.com.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Arda Flanges, All rights reserved