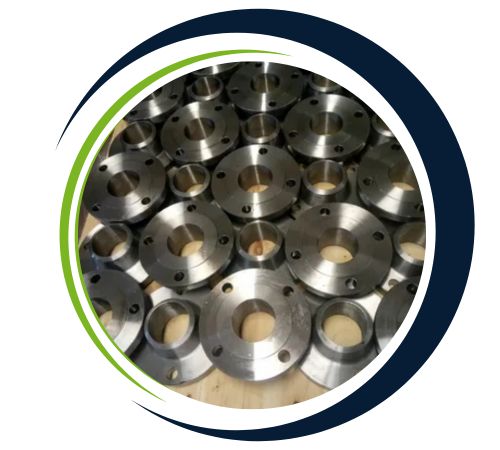

Arda Flanges, based in Istanbul, Turkey, has built a solid reputation as a reliable manufacturer and supplier of DIN 2543 PN16 Slip-On Flanges. They specialize in delivering top-notch solutions for medium-pressure piping systems. These flanges are designed to easily slide over pipes and are welded on both the inside and outside, ensuring a strong and leak-proof connection. Crafted in line with DIN 2543 standards and rated for PN16 pressure, they can handle applications operating up to 16 bar. With state-of-the-art production facilities, rigorous quality control, and adherence to international standards, Arda Flanges guarantees durable, dependable, and cost-effective flange solutions for a wide range of industrial pipelines and equipment.

Typically made from carbon steel, stainless steel, or alloy steel, DIN 2543 PN16 Slip-On Flanges boast impressive mechanical strength, corrosion resistance, and dimensional stability. They provide the necessary tensile and yield strength for medium-pressure applications, along with good toughness and ductility. The slip-on design makes alignment and installation a breeze compared to welded neck flanges, while the full welding ensures a robust, long-lasting, and leak-proof connection. Their PN16 rating makes them perfect for medium-pressure industrial applications that demand reliable performance.

Arda Flanges, a leading supplier in Istanbul, Turkey, offers an extensive selection of DIN 2543 PN16 Slip On Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

| Size Chart | 1/2″ (15 NB) To 48″ (1200NB) |

| Coating Flanges Faces | Zinc Plated, Oil Black Paint, Yellow Transparent, Cold and Hot Dip Galvanized, Anti-rust Paint |

| Design For Size | DIN, EN, ASA, PN, JIS, BS, ANSI, ASME |

| Pressure Rating Table | Class 150 LBS, Class 300 LBS, Class 600 LBS, Class 900 LBS, Class 1500 LBS, Class 2500 LBS |

| Supporting Flanges Material | Flanges Bolts, Gasket, Ring Joint |

| Connect Type Type | FF, RTJ, SMF, LMF, RF, LJF |

| Production Process | Forged, Heat Treated and Machined |

| Standard | ASME B16.38 Flange, DIN Flange, ISO Flange, JIS Flange, PN Flange, MSS SP44 Flange, EN-1092 Flange, BS10 Flange, ASME B16.47 (Series A, Series B) Flange, UNI Flange, ASME B16.5 Flange, AWWA Flange, DIN Flange, GOST Flange |

| Machining Equipment | Bending machine, Sand-blasting machine, Press machine, Pushing Machine, Electric bevelling machine etc |

|

Rated |

d1 |

D |

b |

k |

h1 |

d3 |

s |

r |

h2 |

d4 |

f |

Holes |

Thread |

d2 |

Kg |

|

|

Diameter |

ISO Series |

DIN Series |

||||||||||||||

|

15 |

– |

20 |

95 |

14 |

65 |

35 |

30 |

2 |

4 |

6 |

45 |

2 |

4 |

M 12 |

14 |

0,648 |

|

21,3 |

– |

32 |

||||||||||||||

|

20 |

– |

25 |

105 |

16 |

75 |

38 |

38 |

2,3 |

4 |

6 |

58 |

2 |

4 |

M 12 |

14 |

0,952 |

|

26,9 |

– |

40 |

||||||||||||||

|

25 |

– |

30 |

115 |

16 |

85 |

38 |

42 |

2,6 |

4 |

6 |

68 |

2 |

4 |

M 12 |

14 |

1,14 |

|

33,7 |

– |

45 |

||||||||||||||

|

32 |

– |

38 |

140 |

16 |

100 |

40 |

52 |

2,6 |

6 |

6 |

78 |

2 |

4 |

M 16 |

18 |

1,69 |

|

42,4 |

– |

56 |

||||||||||||||

|

40 |

– |

44,5 |

150 |

16 |

110 |

42 |

60 |

2,6 |

6 |

7 |

88 |

3 |

4 |

M 16 |

18 |

1,86 |

|

48,3 |

– |

64 |

||||||||||||||

|

50 |

– |

57 |

165 |

18 |

125 |

45 |

72 |

2,9 |

6 |

8 |

102 |

3 |

4 |

M 16 |

18 |

2,53 |

|

60,3 |

– |

75 |

||||||||||||||

|

65 |

76,1 |

– |

185 |

18 |

145 |

45 |

90 |

2,9 |

6 |

10 |

122 |

3 |

4 |

M 16 |

18 |

3,06 |

|

80 |

88,9 |

– |

200 |

20 |

160 |

50 |

105 |

3,2 |

8 |

10 |

138 |

3 |

8 |

M 16 |

18 |

3,7 |

|

100 |

– |

108 |

220 |

20 |

180 |

52 |

125 |

3,6 |

8 |

12 |

158 |

3 |

8 |

M 16 |

18 |

4,62 |

|

114,3 |

– |

131 |

||||||||||||||

|

125 |

– |

133 |

250 |

22 |

210 |

55 |

150 |

4 |

8 |

12 |

188 |

3 |

8 |

M 16 |

18 |

6,3 |

|

139,7 |

– |

156 |

||||||||||||||

|

150 |

– |

159 |

285 |

22 |

240 |

55 |

175 |

4,5 |

10 |

12 |

212 |

3 |

8 |

M 20 |

22 |

7,75 |

|

168,3 |

– |

184 |

||||||||||||||

|

200 |

219,1 |

– |

340 |

24 |

295 |

62 |

235 |

5,9 |

10 |

16 |

268 |

3 |

8 |

M 20 |

22 |

11,3 |

|

250 |

– |

267 |

395 |

26 |

350 |

68 |

285 |

6,3 |

12 |

16 |

320 |

3 |

12 |

M 20 |

22 |

14,7 |

|

273 |

– |

292 |

||||||||||||||

|

300 |

323,9 |

– |

445 |

26 |

400 |

68 |

344 |

7,1 |

12 |

16 |

370 |

4 |

12 |

M 20 |

22 |

17,4 |

|

350 |

355,6 |

– |

505 |

26 |

460 |

68 |

385 |

7,1 |

12 |

16 |

430 |

4 |

16 |

M 20 |

22 |

23,6 |

|

– |

368 |

21,6 |

||||||||||||||

|

400 |

406,4 |

– |

565 |

26 |

515 |

72 |

440 |

7,1 |

12 |

16 |

482 |

4 |

16 |

M 24 |

26 |

28,6 |

|

– |

419 |

26,2 |

||||||||||||||

|

(450) |

457 |

– |

615 |

28 |

565 |

72 |

488 |

7,1 |

12 |

16 |

532 |

4 |

20 |

M 24 |

26 |

31,5 |

|

500 |

508 |

– |

670 |

28 |

620 |

75 |

542 |

7,1 |

12 |

16 |

585 |

4 |

20 |

M 24 |

26 |

38,1 |

|

600 |

610 |

– |

780 |

28 |

725 |

80 |

642 |

7,1 |

12 |

18 |

685 |

5 |

20 |

M 27 |

30 |

44,6 |

|

700 |

711 |

– |

895 |

30 |

840 |

80 |

745 |

8 |

12 |

18 |

800 |

5 |

24 |

M 27 |

30 |

62,4 |

|

800 |

813 |

– |

1015 |

32 |

950 |

90 |

850 |

8 |

12 |

18 |

905 |

5 |

24 |

M 30 |

33 |

84,1 |

|

900 |

914 |

– |

1115 |

34 |

1050 |

95 |

950 |

10 |

12 |

20 |

1005 |

5 |

28 |

M 30 |

33 |

98,5 |

|

1000 |

1016 |

– |

1230 |

34 |

1160 |

95 |

1052 |

10 |

16 |

20 |

1110 |

5 |

28 |

M 33 |

36 |

115 |

These flanges find their place in various industries, including oil and gas, chemical processing, petrochemical, water treatment, and power generation. They are perfect for connecting pipelines, pumps, valves, and pressure vessels in medium-pressure systems, ensuring secure sealing and operational efficiency. Commonly used in industrial fluid transfer, chemical lines, and water distribution pipelines, DIN 2543 PN16 Slip-On Flanges provide a trustworthy and enduring solution for industrial applications that require safe and efficient flange connections.

Yes, we offer custom sizes for DIN 2543 PN16 Slip On Flanges to meet specific project needs. Our team at Arda Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@ardaflanges.com.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Arda Flanges, All rights reserved