Arda Flanges, based in Istanbul, Turkey, stands out as a top manufacturer and supplier of Duplex Steel 2205 Flanges, known for their high-quality products tailored for tough industrial settings. Crafted from grade 2205, these flanges strike a remarkable balance between strength and resistance to corrosion, often surpassing many standard stainless steels. Their durability and cost-effectiveness make Duplex Steel 2205 Flanges perfect for environments that are harsh, such as those involving seawater and aggressive chemicals. With state-of-the-art production facilities and rigorous quality checks, Arda Flanges guarantees that its Duplex Steel 2205 Flanges adhere to global standards, earning them a reputation as a reliable choice for industries around the globe.

These flanges are made up of about 22% chromium, 5–6% nickel, 3% molybdenum, and some nitrogen, resulting in a unique dual-phase microstructure of austenite and ferrite. This specific composition provides outstanding resistance to stress corrosion cracking, pitting, and crevice corrosion caused by chlorides, making them a more dependable option than traditional stainless steels. On the mechanical side, Duplex 2205 boasts nearly double the tensile and yield strength of standard austenitic stainless steels, while still offering good ductility and toughness. These characteristics ensure they perform well under varying pressure and temperature conditions, boosting the safety and longevity of connected systems.

| Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

|---|---|

| JIS | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| UNI | 6Bar 10Bar 25Bar 16Bar 40Bar |

| EN | 25Bar 6Bar 10Bar 16Bar 40Bar |

| Connect Type/ Flange Face Type | Ring Type Joint (RTJ), Raised Face (RF), Lap-Joint Face (LJF), Small Male-Female (SMF), Flat Face (FF), Large Male-Female (LMF), Small Tongue, Large Tongue & Groove, Groove |

| Uses & application |

|

| Pressure Rating ANSI | 600 LBS, 900 LBS, 150 LBS, 2500 LBS, 300 LBS, 1500 LBS |

| Pressure Calculation in DIN | 16Bar 6Bar 25Bar 40Bar 10Bar / PN10 PN16 PN6 PN25 PN64 PN40 |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Coating | Zinc Plated,Oil Black Paint, Cold and Hot Dip Galvanized, Anti-rust Paint, Yellow Transparent |

| Most common types | Threaded / Screwed / Forged / Plate |

| Equipment | Pushing Machine, Press machine, electric bevelling machine, Bending machine, Sand-blasting machine etc |

| Origin | West Europe / Japan / Indian / USA / Korean |

| Test | Direct-reading Spectrograph, UI trasonic flaw detector, Hydrostatic testing machine, X-ray detector, Magnetic particle detector |

| Standards | API605, ANSI/ASME B16.5, B16.47 Series A & B, B16.48, ASME Flanges, API7S-15, API7S-43, BS Flanges, DIN Flanges, EN Flanges, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, EN1092 |

| Export to | Dubai, Singapore, Indonesia, Ukraine, Korea, Iran, India, Saudi Arabia, Thailand, Egypt, Oman, Spain, Canada, USA, Ireland, Brazil, Peru, etc |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS 15 NB (1/2″) to 200 NB (8″) Equal and Reducing Configurations |

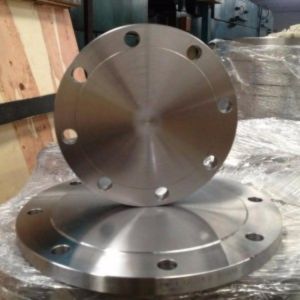

Arda Flanges, a leading supplier in Istanbul, Turkey, offers an extensive selection of Duplex Steel Flanges 2205, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

Duplex Steel 2205 Flanges find their place in various industries, including oil and gas, chemical processing, petrochemical, power generation, marine, and desalination. They are well-suited for pipelines, pressure vessels, heat exchangers, pumps, and valves that face corrosive environments and significant mechanical stresses. Offshore platforms and subsea equipment benefit from their ability to withstand seawater and chloride-rich conditions, while chemical plants depend on their resilience in acidic and oxidizing environments. With their exceptional combination of strength, corrosion resistance, and cost efficiency, Duplex Steel 2205 Flanges are truly a standout choice.

| C | N | P | Si | Mn | Mo | Fe | Cr | S | Ni |

| 1.0 | 0.03 | 0.02 | 2.0 | 3.0 – 3.5 | 22.0 – 23.0 | 0.03 | 4.5 – 6.5 | 0.14 – 0.2 | Bal |

| Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Co-eff of Thermal Expansion (μm/m/°C) | Thermal Conductivity (W/m.K) | Specific Heat 0-100°C ( J/kg.K) | Electrical Resistivity (nΩ.m) | |||

| 0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

| 2205 | 782 | 190 | 13.7 | 14.2 | – | 19 | – | 418 | 850 |

| Density | Melting Point | Yield Strength (0.2%Offset) | Tensile Strength | Elongation |

| 7.8 g/cm3 | 1350 °C (2460 °F) | Psi – 80000 , MPa – 550 | Psi – 116000 , MPa – 800 | 15 % |

Yes, we offer custom sizes for Duplex Steel Flanges 2205 to meet specific project needs. Our team at Arda Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@ardaflanges.com.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Arda Flanges, All rights reserved