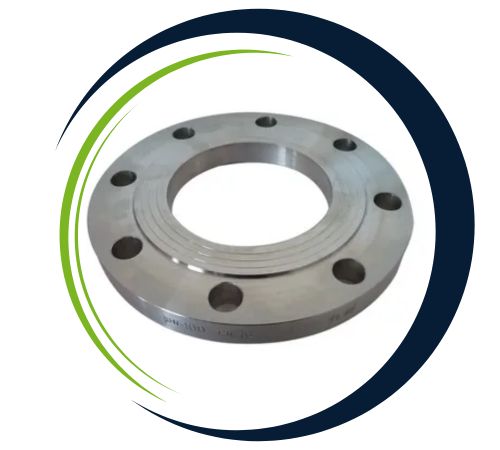

Arda Flanges, located in Istanbul, Turkey, is a well-respected manufacturer and supplier of **Stainless Steel 253MA Flanges**, providing top-notch solutions for both local and international industries. The company is celebrated for its precision engineering and commitment to international standards, offering flanges that guarantee exceptional reliability and durability, even in the toughest conditions. Designed to resist oxidation and scaling at high temperatures, Stainless Steel 253MA Flanges are perfect for industries that deal with intense heat. With a strong emphasis on innovation, quality, and customer satisfaction, Arda Flanges has become a trusted ally for essential industrial piping and structural system needs.

**Stainless Steel 253MA Flanges** are mainly made up of chromium, nickel, and nitrogen, with some rare earth metals and silicon added to boost oxidation resistance. This unique blend gives the alloy impressive mechanical strength and outstanding resistance to corrosion at high temperatures. These flanges are known for their high tensile strength, good creep resistance, and remarkable toughness, even when exposed to elevated temperatures for extended periods. Their excellent weldability, formability, and reliability in harsh environments make them ideal for applications that demand long-lasting performance under thermal and mechanical stress.

| Standards | ANSI/ASME B16.5, EN Flanges, BS 10, B16.47 Series A & B, EN-1092, ASME Flanges, BS Flanges, B16.48, DIN, DIN Flanges, GOST Flanges, ANSI Flanges, BS4504. |

| Size | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Pressure Rating | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Production technique | Forged, Heat treated and machined |

|

Special design |

As per your drawing |

| AS, ANSI, BS, DIN and JIS | |

| 15 NB (1/2″) to 200 NB (8″) | |

| Equal and Reducing Configurations | |

| Connect Type/ Flange Face Type | Ring Type Joint (RTJ), Small Tongue, Raised Face (RF), Lap-Joint Face (LJF), Small Male-Female (SMF), Flat Face (FF), Large Tongue & Groove, Large Male-Female (LMF). |

| Largest Bore Diameter Sizes | NPS ≤ 10 |

| Minimum & Maximum Size | 1/2″ To 48″ |

| Origin | Indian / Japan / Korean / West Europe / USA |

| JIS Standard | 5K, 10 K, 16 K 20 K, 30 K, 40 K, 63 K |

| A182 Flange EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

|

Test Certificates |

EN 10204/3.1B |

| Raw Materials Certificate | |

| 100% Radiography Test Report | |

| Third Party Inspection Report, etc. | |

| Application | Gas, Power, Chemical, Metallurgy, Petroleum, Shipbuilding, Construction etc. |

| Grade | C | Ni | Si | N | S | Mn | P | Cr | Ce | Fe |

| 253 MA | 0.05 – 0.10 | 10.00-12.0 max | 1.40 -2.00 max | 0.14-0.20 max | 1.40-2.00 max | 0.80 max | 0.04 max | 20.00 – 22.00 | 0.03 – 0.08 | Balance |

| Tensile Strength | Elongation | Yield Strength (0.2%Offset) | Hardness |

| 600 | 40% | 310 | 95(Rockwell B) |

Arda Flanges, a leading supplier in Istanbul, Turkey, offers an extensive selection of Stainless Steel 253MA flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

| STANDARD | WERKSTOFF NR. | UNS |

| 253 MA | 1.4835 | S30815 |

Stainless Steel 253MA flanges are widely used in industries requiring high-temperature and corrosion-resistant materials. They are commonly employed in power generation, petrochemical, and chemical processing plants, particularly in environments with elevated temperatures and aggressive chemicals. Due to their excellent creep strength and oxidation resistance, these flanges are ideal for heat exchangers, boilers, and furnace applications. Additionally, they are used in manufacturing equipment for the aerospace and marine industries, where high strength and resistance to thermal fatigue are essential for durability and performance.

| Nominal Size | Outside Diameter (OD) | Min. Thickness (T) | RF Dia. (R) | No. of Bolt Holes | Diameter of Holes | Bolt Circle (BC) | SO Bore ID (SB) | WN Bore ID (WB) | Dia. Hub Base (HB) | Dia. of Hub Top (HT) | SO LTH (SL) | WN LTH (WL) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1⁄2 | 3.50 | 0.38 | 1.38 | 4 | 0.62 | 2.38 | 0.88 | 0.62 | 1.19 | 0.84 | 0.56 | 1.81 |

| 3⁄4 | 3.88 | 0.44 | 1.69 | 4 | 0.62 | 2.75 | 1.09 | 0.82 | 1.50 | 1.05 | 0.56 | 2.00 |

| 1 | 4.25 | 0.50 | 2.00 | 4 | 0.62 | 3.12 | 1.36 | 1.05 | 1.94 | 1.32 | 0.62 | 2.12 |

| 11⁄4 | 4.62 | 0.56 | 2.50 | 4 | 0.62 | 3.50 | 1.70 | 1.38 | 2.31 | 1.66 | 0.75 | 2.19 |

| 11⁄2 | 5.00 | 0.62 | 2.88 | 4 | 0.62 | 3.88 | 1.95 | 1.61 | 2.56 | 1.90 | 0.81 | 2.38 |

| 2 | 6.00 | 0.69 | 3.62 | 4 | 0.75 | 4.75 | 2.44 | 2.07 | 3.06 | 2.38 | 0.94 | 2.44 |

| 21⁄2 | 7.00 | 0.81 | 4.12 | 4 | 0.75 | 5.50 | 2.94 | 2.47 | 3.56 | 2.88 | 1.06 | 2.69 |

| 3 | 7.50 | 0.88 | 5.00 | 4 | 0.75 | 6.00 | 3.57 | 3.07 | 4.25 | 3.50 | 1.12 | 2.69 |

| 31⁄2 | 8.50 | 0.88 | 5.50 | 8 | 0.75 | 7.00 | 4.07 | 3.55 | 4.81 | 4.00 | 1.19 | 2.75 |

| 4 | 9.00 | 0.88 | 6.19 | 8 | 0.75 | 7.50 | 4.57 | 4.03 | 5.31 | 4.50 | 1.25 | 2.94 |

| 5 | 10.00 | 0.88 | 7.31 | 8 | 0.88 | 8.50 | 5.66 | 5.05 | 6.44 | 5.56 | 1.38 | 3.44 |

| 6 | 11.00 | 0.94 | 8.50 | 8 | 0.88 | 9.50 | 6.72 | 6.07 | 7.56 | 6.63 | 1.50 | 3.44 |

| 8 | 13.50 | 1.06 | 10.62 | 8 | 0.88 | 11.75 | 8.72 | 7.98 | 9.69 | 8.63 | 1.69 | 3.94 |

| 10 | 16.00 | 1.12 | 12.75 | 12 | 1.00 | 14.25 | 10.88 | 10.02 | 12.00 | 10.75 | 1.88 | 3.94 |

| 12 | 19.00 | 1.19 | 15.00 | 12 | 1.00 | 17.00 | 12.88 | 12.00 | 14.38 | 12.75 | 2.12 | 4.44 |

| 14 | 21.00 | 1.31 | 16.25 | 12 | 1.12 | 18.75 | 14.14 | 13.25 | 15.75 | 14.00 | 2.19 | 4.94 |

| 16 | 23.50 | 1.38 | 18.50 | 16 | 1.12 | 21.25 | 16.16 | 15.25 | 18.00 | 16.00 | 2.44 | 4.94 |

| 18 | 25.00 | 1.50 | 21.00 | 16 | 1.25 | 22.75 | 18.18 | 17.25 | 19.88 | 18.00 | 2.62 | 5.44 |

| 20 | 27.50 | 1.62 | 23.00 | 20 | 1.25 | 25.00 | 20.20 | 19.25 | 22.00 | 20.00 | 2.81 | 5.62 |

| 22 | 29.50 | 1.75 | 25.25 | 20 | 1.38 | 27.25 | 22.22 | 21.25 | 24.25 | 22.00 | 3.07 | 5.82 |

| 24 | 32.00 | 1.81 | 27.25 | 20 | 1.38 | 29.50 | 24.25 | 23.25 | 26.12 | 24.00 | 3.19 | 5.94 |

| Standard | Class | Diameter | Bolt Circle Diameter | Number of Bolts | Bolt Size | Diameter of Bolt Hole |

|---|---|---|---|---|---|---|

| AS4087 | PN14 | 95 | 67 | 4 | M12 | 14 |

| AS 2129 | Table C | 95 | 67 | 4 | 13 | 14 |

| Table D | 95 | 67 | 4 | 13 | 14 | |

| Table E | 95 | 67 | 4 | 13 | 14 | |

| Table F | 95 | 67 | 4 | 13 | 14 | |

| Table H | 114 | 83 | 4 | 16 | 17 | |

| Table J | 114 | 83 | 4 | 16 | 17 | |

| ANSI B16.5 | ANSI 150 | 89 | 60 | 4 | 13 | 16 |

| ANSI 300 | 95 | 67 | 4 | 13 | 16 | |

| ANSI 600 | 95 | 67 | 4 | 13 | 16 | |

| ANSI 900 | 121 | 83 | 4 | 19 | 22 | |

| ANSI 1500 | 121 | 83 | 4 | 19 | 22 | |

| ISO 7005 (DIN) | PN6 | 80 | 55 | 4 | M10 | 11 |

| PN10 | 95 | 65 | 4 | M12 | 14 | |

| PN16 | 95 | 65 | 4 | M12 | 14 | |

| PN20 | 90 | 60.5 | 4 | M14 | 16 | |

| PN25 | 95 | 65 | 4 | M12 | 14 | |

| PN40 | 95 | 65 | 4 | M12 | 14 |

**Stainless Steel 253MA Flanges** find their place in various industries that need dependable performance in high-temperature settings. They are commonly used in heat exchangers, power generation facilities, petrochemical processing plants, and the cement industry. In furnace components, kilns, and incinerators, these flanges excel in resisting thermal fatigue and oxidation. Their role in gas processing, refineries, and flue gas cleaning systems showcases their ability to endure extreme conditions. Moreover, they are also employed in boilers, steam systems, and other thermal applications where both strength and corrosion resistance are crucial.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Arda Flanges, All rights reserved