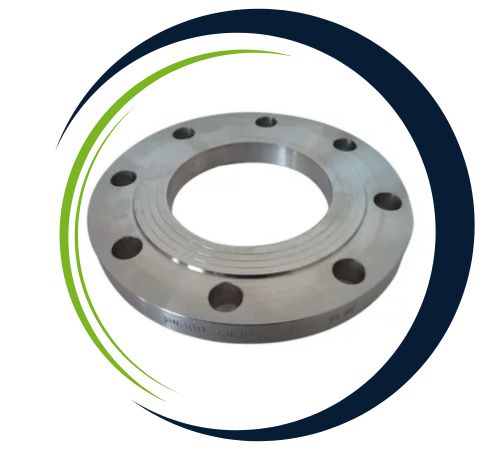

Arda Flanges, based in Istanbul, Turkey, stands out as a top manufacturer and supplier of high-quality Stainless Steel 309H Flanges. Designed to excel in high-temperature and corrosive settings, these flanges are crafted using cutting-edge forging and machining methods, all while adhering to strict quality standards. The Stainless Steel 309H Flanges are known for their impressive strength, durability, and resistance to oxidation, making them ideal for tough industrial applications. With a global clientele, Arda Flanges delivers precision-engineered flange solutions for sectors like chemical processing, power generation, petrochemicals, and heat treatment. These flanges guarantee reliable, long-lasting, and safe connections in critical piping systems that face extreme conditions.

Stainless Steel 309H Flanges are made from a high-chromium (about 23%) and nickel (around 13%) austenitic stainless steel, with a higher carbon content to boost high-temperature strength. They showcase remarkable tensile and yield strength, along with good ductility, toughness, and outstanding resistance to oxidation and scaling at elevated temperatures. These flanges remain stable under thermal stress and offer long-lasting durability in harsh industrial environments. Additionally, Stainless Steel 309H Flanges provide excellent weldability, machinability, and precise dimensions, ensuring secure, leak-proof connections in pipelines, heat exchangers, furnaces, and other high-temperature equipment.

| Specifications | ASTM A182 / ASME SA182 |

| Flange size range | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Flanges Dimensions | ANSI/ ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. |

| Flanges Standard | ANSI Flanges, AWWA Flanges, ASME Flanges, BS 10 Table D Flanges, Table E Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flanges. |

| Pressure Class / Rating | Class 150 LBS, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. |

| Flange Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Large Male-Female (LMF), Flat Face (FF), Small Male-Female (SMF), Lap-Joint Face (LJF), Small Tongue, Large Tongue & Groove |

| Specialized manufacturer of | Weld Neck Ring Flanges (WNRF), Slip-On Ring Flanges (SORF), Blind Ring Flanges (BLRF), Socket Weld Ring Flanges (SWRF), Lap Joint Ring Flanges (LJRF), Ring Type Joint Flanges (RTJF), Large Diameter Flanges, Orifice Flanges |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Grade | C | Mn | Si | P | S | Cr | Ni | Fe | |

| SS 309H | 0.04-0.10 | 2.0 | 0.75 | 0.045 | 0.03 | 22.0-24.0 | 15.0 | 58.0-63.0 | |

| Grade | Tensile Strengtd ksi (min) | Yield Strength 0.2% ksi (min) | Elongation % | Hardness (Brinell) max |

| 309H | 40 | 30 | 40 | 217 |

Arda Flanges, a leading supplier in Istanbul, Turkey, offers an extensive selection of Stainless Steel 309H flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

| STANDARD | WERKSTOFF NR. | UNS |

| SS 309H | 1.4833 | S30909 |

| Density lbm/in3 | Thermal Conductivity (BTU/h ft. °F) | Electrical Resistivity (in x 10-6) | Modulus of Elasticity (psi x 106 | Coefficient of Thermal Expansion (in/in)/ °F x 10-6 | Specific Heat (BTU/lb/ °F) | Melting Range (°F) |

| at 68°F: 0.285 | 9.4 at 212°F | 28.3 at 68°F | 28 | 9.4 at 32 – 212°F | 0.1200 at 68°F to 212°F | 2500 to 2590 |

| 12.4 at 932 °F | 39.4 at 752°F | 10.2 at 32 – 1000°F | ||||

| 49.6 at 1652 °F | 10.4 at 32 – 1500°F |

Stainless Steel 309H Flanges are a go-to choice in industries that need to withstand high temperatures, resist corrosion, and maintain mechanical strength. You’ll find them in places like furnaces, boilers, heat exchangers, chemical processing units, petrochemical plants, and power generation facilities. These flanges are also essential for pipelines, pressure vessels, and reactors that operate under extreme thermal and corrosive conditions. They offer secure, leak-proof, and durable connections, ensuring that systems run smoothly. With their excellent resistance to scaling, oxidation, and thermal fatigue, Stainless Steel 309H Flanges are crucial for high-temperature industrial applications where safety, efficiency, and long-lasting durability are key to keeping processes running smoothly.

| NPS | O.D. of Flange | Flanges Thickness | Diameter of RF | Diameter of Hub at Base | Lengtd Tdru Hub | Bore or Diameter | Dia. of Hub at Bevel | Radius of Fillet | Deptd of Socket | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Welding (WN) Neck | Slip-On (SORF) Threaded (NPT) Socket (SWRF) | Lap Joint (Loose) | Slip-on (SORF) Socket (SWRF) | Lap Joint (Loose) | ||||||||

| O | Q | R | X | Y | Y | Y | W | B | H | r | Z | |

| 1/2 | 3-1/2 | 7/16 | 1-3/8 | 1-3/16 | 1-7/8 | 5/8 | 5/8 | .88 | .90 | .84 | 1/8 | 3/8 |

| 3/4 | 3-7/8 | 1/2 | 1-11/16 | 1-1/2 | 2-1/16 | 5/8 | 5/8 | 1.09 | 1.11 | 1.05 | 1/8 | 7/16 |

| 1 | 4-1/4 | 9/16 | 2 | 1-15/16 | 2-3/16 | 11/16 | 11/16 | 1.36 | 1.38 | 1.32 | 1/8 | 1/2 |

| 1-1/4 | 4-5/8 | 5/8 | 2-1/2 | 2-5/16 | 2-1/4 | 13/16 | 13/16 | 1.70 | 1.72 | 1.66 | 3/16 | 9/16 |

| 1-1/2 | 5 | 11/16 | 2-7/8 | 2-9/16 | 2-7/16 | 7/8 | 7/8 | 1.95 | 1.97 | 1.90 | 1/4 | 5/8 |

| 2 | 6 | 3/4 | 3-5/8 | 3-1/16 | 2-1/2 | 1 | 1 | 2.44 | 2.46 | 2.38 | 5/16 | 11/16 |

| 2-1/2 | 7 | 7/8 | 4-1/8 | 3-9/16 | 2-3/4 | 1-1/8 | 1-1/8 | 2.94 | 2.97 | 2.88 | 5/16 | 3/4 |

| 3 | 7-1/2 | 15/16 | 5 | 4-1/4 | 2-3/4 | 1-3/16 | 1-3/16 | 3.57 | 3.60 | 3.50 | 3/8 | 13/16 |

| 3-1/2 | 8-1/2 | 15/16 | 5-1/2 | 4-13/16 | 2-13/16 | 1-1/4 | 1-1/4 | 4.07 | 4.10 | 4.00 | 3/8 | 7/8 |

| 4 | 9 | 15/16 | 6-3/16 | 5-5/16 | 3 | 1-5/16 | 1-5/16 | 4.57 | 4.60 | 4.50 | 7/16 | 15/16 |

| 5 | 10 | 15/16 | 7.5/16 | 6-7/16 | 3-1/2 | 1-7/16 | 1-7/16 | 5.66 | 5.69 | 5.56 | 7/16 | 15/16 |

| 6 | 11 | 1 | 8-1/2 | 7-9/16 | 3-1/2 | 1-9/16 | 1-9/16 | 6.72 | 6.75 | 6.63 | 1/2 | 1-1/16 |

| 8 | 13-1/2 | 1-1/8 | 10-5/8 | 9-11/16 | 4 | 1-3/4 | 1-3/4 | 8.72 | 8.75 | 8.63 | 1/2 | 1-1/4 |

| 10 | 16 | 1-3/16 | 12-3/4 | 12 | 4 | 1-15/16 | 1-15/16 | 10.88 | 10.92 | 10.75 | 1/2 | 1-5/16 |

| 12 | 19 | 1-1/4 | 15 | 14-3/8 | 4-1/2 | 2-3/16 | 2-3/16 | 12.88 | 12.92 | 12.75 | 1/2 | 1-9/16 |

| 14 | 21 | 1-3/8 | 16-1/4 | 15-3/4 | 5 | 2-1/4 | 3-1/8 | 14.14 | 14.18 | 14.00 | 1/2 | 1-5/8 |

| 16 | 23-1/2 | 1-7/16 | 18-1/2 | 18 | 5 | 2-1/2 | 3-7/16 | 16.16 | 16.19 | 16.00 | 1/2 | 1-3/4 |

| 18 | 25 | 1-9/16 | 21 | 19-7/8 | 5-1/2 | 2-11/16 | 3-13/16 | 18.18 | 18.20 | 18.00 | 1/2 | 1-15/16 |

| 20 | 27-1/2 | 1-11/16 | 23 | 22 | 5-11/16 | 2-7/8 | 4-1/16 | 20.20 | 20.25 | 20.00 | 1/2 | 2-1/8 |

| 24 | 32 | 1-7/8 | 27-1/4 | 26-1/8 | 6 | 3-1/4 | 4-3/8 | 24.25 | 24.25 | 24.00 | 1/2 | 2-1/2 |

| Nominal Pipe Sizes (NPS) | Slip On (SORF) | Threaded (NPT) | Socket Weld (SWRF) | Lap Joint (Loose) | Blind (BLRF) | Weld Neck (WRNR) |

|---|---|---|---|---|---|---|

| ½ | 1 | 1 | 2 | 1 | 2 | 2 |

| ¾ | 2 | 2 | 2 | 2 | 2 | 2 |

| 1 | 2 | 2 | 2 | 2 | 2 | 3 |

| 1¼ | 3 | 3 | 3 | 3 | 3 | 3 |

| 1½ | 3 | 3 | 3 | 3 | 4 | 4 |

| 2 | 5 | 5 | 5 | 5 | 5 | 6 |

| 2½ | 8 | 8 | 8 | 8 | 7 | 10 |

| 3 | 9 | 9 | 9 | 9 | 9 | 11.5 |

| 3½ | 11 | 12 | 11 | 11 | 13 | 12 |

| 4 | 13 | 13 | 13 | 13 | 17 | 16.5 |

| 5 | 15 | 15 | 15 | 15 | 20 | 21 |

| 6 | 19 | 19 | 19 | 19 | 27 | 26 |

| 8 | 30 | 30 | 30 | 30 | 47 | 42 |

| 10 | 43 | 43 | 43 | 43 | 70 | 54 |

| 12 | 64 | 64 | 64 | 64 | 123 | 88 |

| 14 | 90 | 90 | 90 | 105 | 140 | 114 |

| 16 | 106 | 98 | 98 | 140 | 180 | 140 |

| 18 | 130 | 130 | 130 | 160 | 220 | 165 |

| 20 | 165 | 165 | 165 | 195 | 285 | 197 |

| 22 | 185 | 185 | 185 | 245 | 355 | 225 |

| 24 | 220 | 220 | 220 | 275 | 430 | 268 |

Yes, we offer custom sizes for Stainless Steel 309H flanges to meet specific project needs. Our team at Arda Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@ardaflanges.com.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Arda Flanges, All rights reserved