Arda Flanges, located in Istanbul, Turkey, has made a name for itself as a leading manufacturer and supplier of Super Duplex Steel S32750 Flanges, providing top-notch flange solutions to industries around the globe. These flanges are celebrated for their durability, resistance to corrosion, and impressive mechanical strength, all engineered to meet international standards and perform in the toughest environments. By blending cutting-edge technology with skilled craftsmanship, Arda Flanges produces precision-engineered S32750 flanges that promise a long service life and dependable performance. With a strong focus on innovation, quality, and customer satisfaction, Arda Flanges has become a reliable partner for industries in need of advanced flange solutions.

Super Duplex Steel S32750 Flanges are made up of about 25% chromium, 7% nickel, 4% molybdenum, and nitrogen, resulting in a well-balanced microstructure of austenite and ferrite. This unique composition offers remarkable resistance to chloride-induced stress corrosion cracking, pitting, and crevice corrosion. On the mechanical side, these flanges boast a high tensile strength of up to 800 MPa, excellent yield strength around 550 MPa, and impressive toughness even in low temperatures. Their dual-phase structure provides outstanding fatigue and impact resistance, making them incredibly reliable under extreme pressure and thermal conditions. These characteristics make S32750 flanges perfect for demanding industrial applications that require both strength and corrosion resistance.

Specifications : ASTM A182 / ASME SA182

Dimensions : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Size : 1/8″ NB TO 24″ NB

Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc.

Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Grades : S32750 / S32760 A182 Gr F51 / F52 / F53 / F54 / F55 / F57 / F59 / F60 / F61

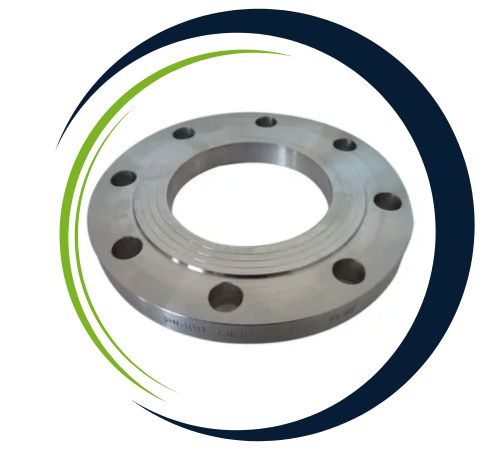

Arda Flanges, a leading supplier in Istanbul, Turkey, offers an extensive selection of Super Duplex Steel S32750 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | Fe |

| S32750 | 0.030 max | 1.20 max | 0.80 max | 0.035 max | 0.020 max | 24.00 – 26.00 | 3.00 – 5.00 | 6.00 – 8.00 | 0.24 – 0.32 | 58.095 min |

| Grades | Density (g/cm 3) | Density (lb/in 3) | Melting Point (°C) | Melting Point (°F) |

| S32750 | 7.8 | 0.281 | 1350 | 2460 |

Super Duplex Steel S32750 Flanges find extensive use in offshore oil and gas platforms, subsea pipelines, chemical processing, and petrochemical industries, where resistance to harsh chloride environments is essential. They’re also utilized in desalination plants, marine engineering, and power generation units due to their resilience against seawater and high-pressure situations. In the pulp and paper industry, they can handle tough bleaching chemicals, while in structural and pressure vessel applications, they ensure safety and long-lasting performance. Their exceptional mechanical properties make them a go-to choice for various challenging applications.

| Nom. Pipe Size | O | T | R | X | No./Dia. of Holes | Bolt Circle Dia. | L2 | H | B2 | L | B | r | L3 | B3 | D |

| 1/2 | 3.5 | 0.44 | 1.38 | 1.19 | 4-0.62 | 2.38 | 1.88 | 0.84 | 0.62 | 0.62 | 0.88 | 0.12 | 0.62 | 0.9 | 0.38 |

| 3/4 | 3.88 | 0.5 | 1.69 | 1.5 | 4-0.62 | 2.75 | 2.06 | 1.05 | 0.82 | 0.62 | 1.09 | 0.12 | 0.62 | 1.11 | 0.44 |

| 1 | 4.25 | 0.56 | 2 | 1.94 | 4-0.62 | 3.12 | 2.19 | 1.32 | 1.05 | 0.69 | 1.36 | 0.12 | 0.69 | 1.38 | 0.5 |

| 1-1/4 | 4.62 | 0.62 | 2.5 | 2.31 | 4-0.62 | 3.5 | 2.25 | 1.66 | 1.38 | 0.81 | 1.7 | 0.19 | 0.81 | 1.72 | 0.56 |

| 1-1/2 | 5 | 0.68 | 2.88 | 2.56 | 4-0.62 | 3.88 | 2.44 | 1.9 | 1.61 | 0.88 | 1.95 | 0.25 | 0.88 | 1.97 | 0.62 |

| 2 | 6 | 0.75 | 3.62 | 3.06 | 4-0.75 | 4.75 | 2.5 | 2.38 | 2.07 | 1 | 2.44 | 0.31 | 1 | 2.46 | 0.69 |

| 2-1/2 | 7 | 0.88 | 4.12 | 3.56 | 4-0.75 | 5.5 | 2.75 | 2.88 | 2.47 | 1.12 | 2.94 | 0.31 | 1.12 | 2.97 | 0.75 |

| 3 | 7.5 | 0.94 | 5 | 4.25 | 4-0.75 | 6 | 2.75 | 3.5 | 3.07 | 1.19 | 3.57 | 0.38 | 1.19 | 3.6 | 0.81 |

| 3-1/2 | 8.5 | 0.94 | 5.5 | 4.81 | 8-0.75 | 7 | 2.81 | 4 | 3.55 | 1.25 | 4.07 | 0.38 | 1.25 | 4.1 | 0.88 |

| 4 | 9 | 0.94 | 6.19 | 5.31 | 8-0.75 | 7.5 | 3 | 4.5 | 4.03 | 1.31 | 4.57 | 0.44 | 1.31 | 4.6 | 0.94 |

| 5 | 10 | 0.94 | 7.31 | 6.44 | 8-0.88 | 8.5 | 3.5 | 5.56 | 5.05 | 1.44 | 5.66 | 0.44 | 1.44 | 5.69 | 0.94 |

| 6 | 11 | 1 | 8.5 | 7.56 | 8-0.88 | 9.5 | 3.5 | 6.63 | 6.07 | 1.56 | 6.72 | 0.5 | 1.56 | 6.75 | 1.06 |

| 8 | 13.5 | 1.12 | 10.62 | 9.69 | 8-0.88 | 11.75 | 4 | 8.63 | 7.98 | 1.75 | 8.72 | 0.5 | 1.75 | 8.75 | 1.25 |

| 10 | 16 | 1.19 | 12.75 | 12 | 12-1.00 | 14.25 | 4 | 10.75 | 10.02 | 1.94 | 10.88 | 0.5 | 1.94 | 10.92 | 1.31 |

| 12 | 19 | 1.25 | 15 | 14.38 | 12-1.00 | 17 | 4.5 | 12.75 | 12 | 2.19 | 12.88 | 0.5 | 2.19 | 12.92 | 1.56 |

| 14 | 21 | 1.38 | 16.25 | 15.75 | 12-1.12 | 18.75 | 5 | 14 | 13.25 | 2.25 | 14.14 | 0.5 | 3.12 | 14.18 | 1.63 |

| 16 | 23.5 | 1.44 | 18.5 | 18 | 16-1.12 | 21.25 | 5 | 16 | 15.25 | 2.5 | 16.16 | 0.5 | 3.44 | 16.19 | 1.75 |

| 18 | 25 | 1.56 | 21 | 19.88 | 16-1.25 | 22.75 | 5.5 | 18 | 17.25 | 2.69 | 18.18 | 0.5 | 3.81 | 18.2 | 1.94 |

| 20 | 27.5 | 1.69 | 23 | 22 | 20-1.25 | 25 | 5.69 | 20 | 19.25 | 2.88 | 20.2 | 0.5 | 4.06 | 20.25 | 2.13 |

| 22 | 29.5 | 1.81 | 25.25 | 24.25 | 20-1.38 | 27.25 | 5.88 | 22 | 21.25 | 3.13 | 22.22 | 0.5 | 4.25 | 22.25 | 2.38 |

| 24 | 32 | 1.88 | 27.25 | 26.12 | 20-1.38 | 29.5 | 6 | 24 | 23.25 | 3.25 | 24.25 | 0.5 | 4.38 | 24.25 | 2.5 |

Yes, we offer custom sizes for Super Duplex Steel S32750 Flanges to meet specific project needs. Our team at Arda Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@ardaflanges.com.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Arda Flanges, All rights reserved