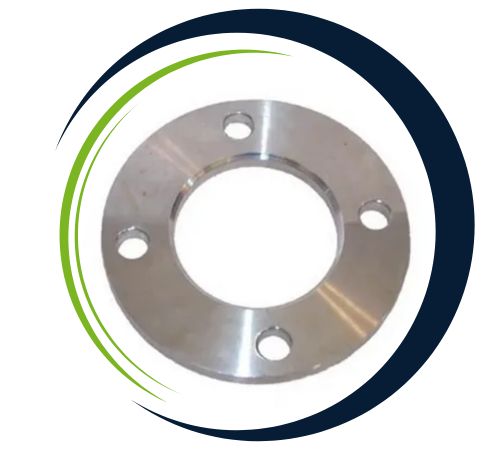

Arda Flanges, a prominent manufacturer and supplier based in Istanbul, Turkey, has built a solid reputation for crafting high-quality flanges that adhere to international standards. Among their impressive lineup, Super Duplex Steel Plate Flanges stand out for their exceptional strength, remarkable resistance to corrosion, and cost-effectiveness. Tailored for high-performance applications, these flanges blend the best features of both ferritic and austenitic stainless steels, ensuring they are durable and reliable. Arda’s Super Duplex Steel Plate Flanges are meticulously engineered to provide secure connections in critical systems, making them a go-to choice for industries that demand long-lasting performance in challenging environments.

Super Duplex Steel Plate Flanges are made up of significant amounts of chromium, molybdenum, and nitrogen, along with a balanced mix of nickel, which boosts their resistance to pitting, stress corrosion cracking, and crevice corrosion. They showcase impressive mechanical properties, including high tensile and yield strength, excellent impact resistance, and outstanding toughness, even in sub-zero temperatures. The duplex microstructure offers enhanced stability, ensuring a robust combination of hardness and ductility. Additionally, these flanges boast excellent weldability and fatigue strength, making them a reliable choice for demanding industrial and marine applications.

| Specification | ASTM A182 / ASME SA182 |

|---|---|

| Size Chart | 1/2″ (15 NB) to 48″ (1200NB) DN10~DN5000 |

| Standards | ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, GOST Flange, ASME/ANSI B16.5/16.36/16.47A/16.47B, MSS S44, ISO70051, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092 |

| Pressure Rating ANSI | Class 150 LBS, 300 LBS, 600 LBS, 900 LBS, 1500 LBS, 2500 LBS |

| Pressure Calculation in DIN | 6Bar 10Bar 16Bar 25Bar 40Bar / PN6 PN10 PN16 PN25 PN40, PN64 |

| UNI | 6Bar 10Bar 16Bar 25Bar 40Bar |

| EN | 6Bar 10Bar 16Bar 25Bar 40Bar |

| Coating | Oil Black Paint, Anti-rust Paint, Zinc Plated, Yellow Transparent, Cold and Hot Dip Galvanized |

| Test Certificates | EN 10204/3.1B Raw Materials Certificate 100% Radiography Test Report Third Party Inspection Report, etc |

| Production Technique | Forged, Heat treated and machined |

| Connect Type/ Flange Face Type | Raised Face (RF), Ring Type Joint (RTJ), Flat Face (FF), Large Male-Female (LMF), Lap-Joint Face (LJF), Small Male-Female (SMF), Small Tongue, Large Tongue & Groove, Groove |

| Special design | As per your drawing AS, ANSI, BS, DIN and JIS 15 NB (1/2″) to 200 NB (8″) Equal and Reducing Configurations |

| Test | Direct-reading Spectrograph, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector, Magnetic particle detector |

| Equipment | Press machine, Bending machine, Pushing Machine, electric bevelling machine, Sand-blasting machine etc |

| Manufacturer of | ANSI DIN, GOST, JIS, UNI, BS, AS2129, AWWA, EN, SABS, NFE etc. BS Flange, EN Flange, API 6A Flange, ANSI Flange, ASME Flange, DIN Flange, EN1092-1 Flange, UNI Flange, JIS/ KS Flange, BS4504 Flange, GB Flange, AWWA C207 Flange, GOST Flange, PSI Flange B.S: BS4504 , BS3293, BS1560, BS10 AS 2129: Table D; Table E; Table H ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings ANSI : ANSI B16.5, ANSI B16.47(API605), MSS SP44, ANSI B16.36, ANSI B16.48 ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, ANSI B16.48 American standard (ANSI) German (DIN) British standard (BS) DIN: DIN 2527, DIN 2566, DIN 2573, DIN 2576, DIN 2641, DIN 2642, DIN 2655, DIN 2656, DIN 2627, DIN 2628, DIN 2629, DIN 2631, DIN 2632, DIN 2633, DIN 2634, DIN 2635, DIN 2636, DIN 2637, DIN 2638 ASTM A182 S32760 Duplex Steel Flanges The other standard: AWWA C207; EN1092-1, GOST12820, JIS B2220; KS B1503, SABS1123; NFE29203; UNI2276 |

| Grades | Super Duplex Steel F53, F52, F55, S32760, S32950, S32750 |

| Material Test Certificates (MTC) as per EN 10204 3.1 and EN 10204 3.2, Test Certificates certifying NACE MR0103, NACE MR0175 | |

Arda Flanges, a premier supplier in Istanbul, Turkey, specializes in high-quality super duplex steel plate flanges. They are valued for their exceptional durability, corrosion resistance, precise engineering, and suitability across diverse industrial applications.

Super Duplex Steel Plate Flanges find their place in various industries that require high strength and corrosion resistance in tough operating conditions. They are frequently used in offshore oil and gas production, chemical processing facilities, desalination plants, shipbuilding, and heat exchangers. Their exceptional resistance to chloride-induced corrosion makes them perfect for marine environments and seawater systems. Furthermore, these flanges are utilized in power generation, pulp and paper, and petrochemical sectors where durability, safety, and long-term performance are essential.

| STANDARD | WERKSTOFF NR. | UNS |

| Super Duplex 2507 | 1.4410 | S32750 / S32760 |

| ASME/ANSI B 16.5 | Plate Flange |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B 16.47 | Blind Flange [Series A & B],Threaded Flange |

| PRESSURE CLASS | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | Plate Flange |

| PRESSURE CLASS | 300, 400, 600, 900, 1500, 2500 |

| PRESSURE CLASS | PN 2.5 TO PN 40 |

| BS 4504[PART 1] | Hubbed Slip-On |

| PRESSURE CLASS | PN 2.5 TO PN 400 |

| BS 1560 BOSS | Hubbed Slip-On Hubbed Threaded |

| PRESSURE CLASS | 150, 300, 400, 600, 900, 1500, 2500 |

| BS10 | Plate Slip-On Flange, Slip-On Boss Flange |

| TABLE | D, E, F, H |

| DIN FLANGES | DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673 |

| PRESSURE CLASS | PN 6 TO PN 100 |

Yes, we offer custom sizes for Super Duplex Steel Plate Flanges to meet specific project needs. Our team at Arda Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@ardaflanges.com.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Arda Flanges, All rights reserved