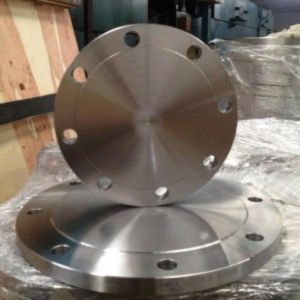

Arda Flanges, located in Istanbul, Turkey, stands out as a top-notch manufacturer and supplier of high-quality Titanium Gr 5 Flanges, catering to a variety of industrial sectors around the globe. With a strong focus on precision engineering and rigorous quality standards, Arda Flanges crafts flanges that not only meet international specifications but also promise long-lasting performance even in tough conditions. Thanks to their state-of-the-art manufacturing facilities and a skilled workforce, they consistently deliver flanges with precise dimensions, excellent surface finishes, and dependable mechanical properties. By prioritizing durability, corrosion resistance, and customer satisfaction, Arda Flanges has earned a reputation as a reliable provider for industries that demand high-performance titanium solutions. Arda Flanges, based in Rotherham, Turkey, is a prominent producer and supplier of top-grade Titanium Grade 5 flanges. They are noted for their superior strength, corrosion resistance, and light weight, and they are highly suitable for challenging uses in aerospace, marine, and chemical sectors. Arda Flanges provides an extensive variety of flange designs such as weld neck, slip-on, blind, and lap joint made of premium Grade 5 titanium (Ti-6Al-4V) for adhering to high international standards like ASTM B381 and ASME B16.5. Through its pledge to precision engineering and customer care, Arda Flanges provides strong, high-performing solutions engineered to suit multifaceted industrial applications.

Titanium Gr 5 Flanges are made from a titanium alloy that consists of about 90% titanium, 6% aluminum, and 4% vanadium. This unique blend gives them an outstanding strength-to-weight ratio, remarkable corrosion resistance, and impressive fatigue strength. On the mechanical side, these flanges boast a tensile strength of up to 950 MPa, a yield strength of around 880 MPa, and an elongation of 10–15%. They maintain their structural integrity even at high temperatures and under cyclic loading, making them perfect for high-performance applications. The combination of their lightweight nature, toughness, and resistance to harsh chemical environments ensures they are reliable in critical industrial operations.

| Standards | GOST Flange, JISB2220, BS1560-3.1, API7S-15, API7S-43, API605, EN1092, BS, BS4504, BS 10, EN-1092, DIN, ANSI, ASME, DIN, MSS S44, ISO70051, ANSI/ASME B16.5, ASME/ANSI B16.5/16.36/16.47A/16.47B, B16.47 Series A & B, B16.48, EN |

|---|---|

| Pressure Rating ANSI | Class 1500, Class 150, Class 900, Class 2500, Class 300, Class 600, |

| Pressure Calculation in DIN | 10Bar, 16Bar, 25Bar, 40Bar, 6Bar, / PN16, PN64, PN40, PN25, PN10, PN6 |

| JIS | 16 K, 20 K, 5K, 10 K, 40 K, 63 K, 30 K, |

| UNI | 10Bar 16Bar 6Bar 25Bar 40Bar |

| EN | 6Bar 25Bar 40Bar 10Bar 16Bar |

| Most common Types | Threaded / Screwed / Forged / Plate |

| Production technique |

|

| Shapes and Types we produce | Large Male-Female (LMF), Ring Type Joint (RTJ), Flat Face (FF), Small Tongue, Small Male-Female (SMF),Raised Face (RF), Large Tongue & Groove, Groove, Lap-Joint Face (LJF) |

| Test | Direct-reading Spectrograph, Magnetic particle detector, Hydrostatic testing machine, X-ray detector, UI trasonic flaw detector |

| Equipment | Pushing Machine, Press machine, Bending machine, Sand-blasting machine, electric bevelling machine etc |

Arda Flanges, a leading supplier in Istanbul, Turkey, offers an extensive selection of Titanium Gr 5 Flanges, including weld neck flanges, slip-on flanges, blind flanges, threaded flanges, and lap joint flanges. Designed for diverse industrial applications, our high-quality inventory and commitment to exceptional service make us a trusted choice for flange products in the region.

Titanium Gr 5 Flanges find their place in industries where strength, corrosion resistance, and durability are non-negotiable. They’re commonly used in chemical processing, petrochemical, aerospace, marine, and power generation sectors. These flanges are particularly suited for pipelines that transport corrosive fluids, high-temperature steam systems, and seawater applications due to their resistance to pitting and crevice corrosion. Moreover, they play a vital role in pharmaceutical, desalination, and offshore oil and gas projects, where reliability in extreme conditions is essential. Their lightweight yet tough characteristics make them a go-to choice for demanding industrial tasks.

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Gr. 5 | 3.7165 | N56400 |

| Grade | Ti | C | Fe | H | N | O | Al | V |

| Ti Grade5 | 90 min | – | 0.25 max | – | – | 0.2 max | 6 min | 4 min |

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Titanium Gr. 5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14 % |

Yes, we offer custom sizes for Titanium Gr 5 Flanges to meet specific project needs. Our team at Arda Flanges is committed to providing tailored solutions for all your requirements. For more details, contact us at sales@ardaflanges.com.

We are renowned for delivering products with precise, accurate dimensions. Each product undergoes thorough testing, both destructive and non-destructive, to ensure quality before being shipped to our customers.

Our team is ready to assist you. Contact us for any queries or personalized solutions.

Copyright 2024 Arda Flanges, All rights reserved